TO DATE

|

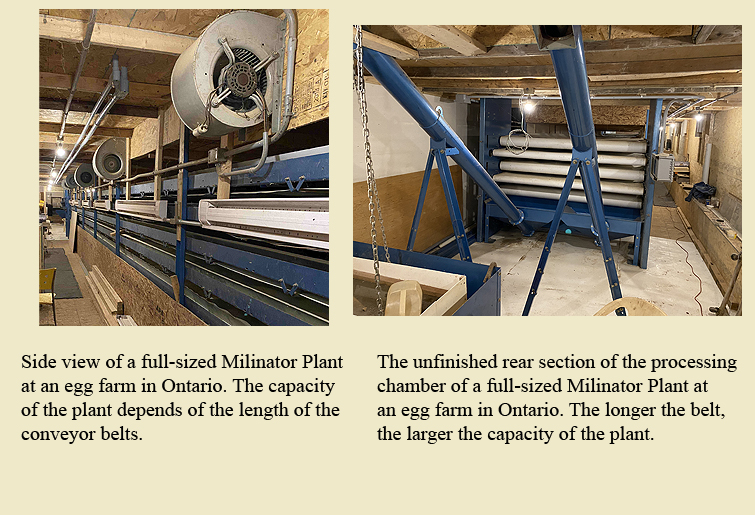

The front section of a full-sized Mechanical Automated Milinator Plant built at an egg farm in Ontario. The processing capacity of this plant is 1.5 tons of chicken manure per day. The manufacture and assembly of this plant is now 80% complete. ______________________________ |

||||

|

______________________________ |

||||

|

The pictures above show various fly cages, which are designed to accommodate different automation requirements. ______________________________ |

||||

|

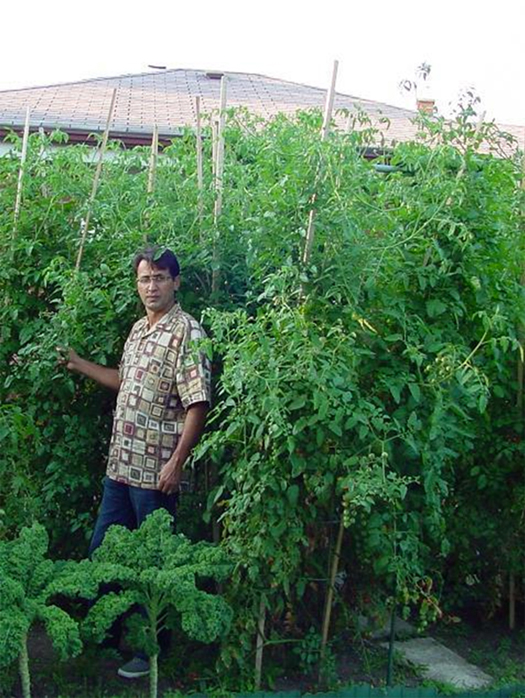

With Cyclorganic, you don't need a big garden to grow a big harvest. ______________________________ |

||||

|

A HYDROPONICS STORE IN OAKVILLE TESTED CYCLORGANIC FERTILIZER The manager decided to test CYCLORGANIC on the plants in his showroom, to see if our claims were true. The effects of CYCLORGANIC were noticeable within a few days and in 2 weeks the results were overwhelming. New leaves grew on all the branches of the citrus tree above and were 4 times larger than the older leaves! ______________________________ |

||||

|

Milinator enclosure. ______________________________ |

||||

|

Ms. Nichelle Lomas received a degree of Master of Science in Environmental Biology, working on her thesis in Milinator prototype plant at Arkell research Station. ______________________________ |

||||

THE FIRST MECHANICAL MILINATOR PROTOTIPE EQUIPMENT LOCATED AT THE UNIVERSITY OF GUELPH RESEARCH FACILITY

The equipment was designed and patented by EcoSpace Engineering Ltd. and produced by the agricultural engineering company Walinga Inc. (www.walinga.com) ______________________________ |

||||

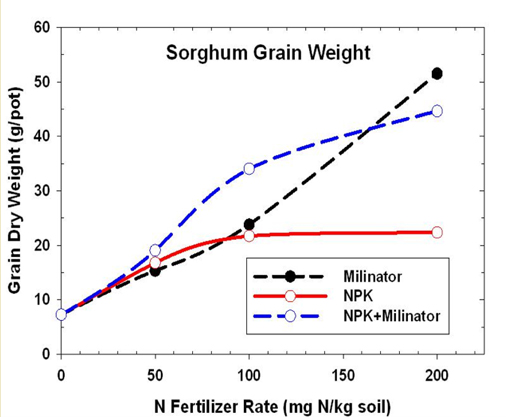

International Fertilizer Development Center conducted field trials of Cyclorganic fertilizer, produced by Milinator technology. Dr. Upendra Singh, Principal scientist of IFDC, gave the preliminary results of the trial to Mrs. Bicky Milin, Vice President of Milinator Technologies Inc. The results were much better than expected. Cyclorganic can produce a much higher yield of Sorghum than commercially available fertilizers, with the same amount of nutrients. Another advantage of Cyclorganic was that it had to be added only once, at the beginning of the trial, while the commercial fertilizer had to be added every week. Click here to view final report of the trial.

______________________________ |

||||

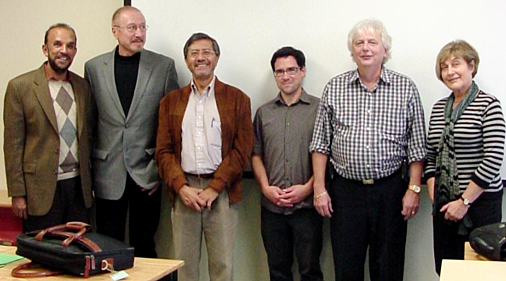

Mr. Sanjib Choudhuri, Executive Director of the VFRC (Virtual Fertilizer Research Center) and Dr. Upendra Singh, Principal scientist (Soil Fertility) of the IFDC, visited La Cité Collégiale in Ottawa to view and discuss the IFDC's field trials of Milinator fertilizer on Tomato plants. This follow-up trial confirmed the IFDC's initial results.

______________________________ |

||||

Milinator Technologies Inc, signed a contract with La Cité Collégiale, Ottawa, Ontario, to conduct field trials and chemical analysis of Milinator fertilizer. The La Cité project is financed by the VFRC (Virtual Fertilizer Research Center, Washington DC, USA) and the Government of Canada. The project is being organized and supervised by Dr. Michel Caron, consultant at La Cité Collégiale in Ottawa.

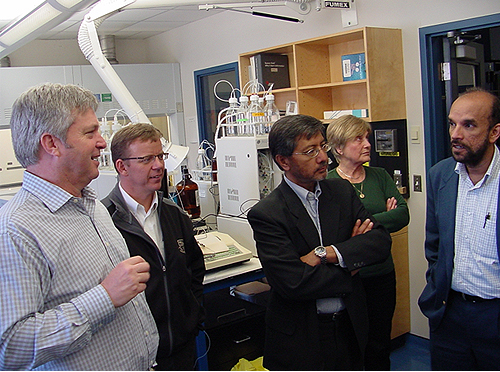

Dr. Michel Caron, P. Ag., Research Advisor at La Cité Collégiale, visiting the Milinator research facility and the Space Research Laboratory, at the University of Guelph, Ontario. ______________________________ |

||||

Sanjib Choudhuri, Executive Director of the VFRC and Dr. Upendra Singh, Principal scientist (Soil Fertility) of the IFDC (International Fertilizer Development Center, Alabama, USA), visited the Milinator prototype facilities at the University of Guelph Research Station and space laboratory in Guelph, Ontario.

Mr. Sanjib Choudhuri (first left) and Dr. Upendra Singh (fourth from left) also visited the Agricultural Space Laboratory at the University of Guelph where Dr. Mike Dixon (third from left) explained how Milinator technology could be used in space travel and in the future colonization and terraforming of other planets. ______________________________ |

||||

In December 2011, Mr. Ivan Milin, President of Ecospace Engineering Ltd., was invited to Algeria to present Milinator technology to the Algerian Ministry of Agriculture and Agricultural University of Tlemcen. The visit was organized by Dr. Mejda Benali, Innovation & Industrial Technology Advisor at Government of Canada. Click here to view Dr. Benali's endorsement letter.

______________________________ |

||||

|

Click here to view the article. ______________________________ |

||||

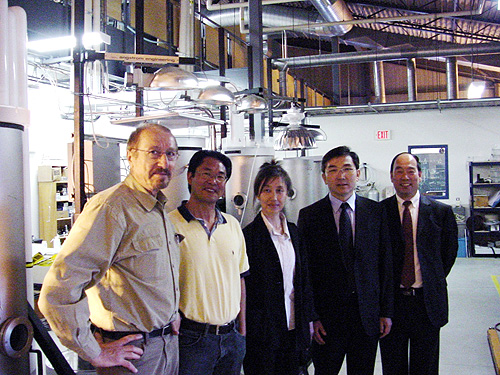

|

Chinese Delegation, Dr. Youbin Zheng and Mr. Ivan Milin pose in front of the hypobaric chambers. Delegation from The Consulate General of the People's Republic of China, visited the Milinator prototype plant and Space Laboratory for Agricultural Research. Members of delegation are (from right to left): Mr. Sun Yongjian, Consul for Science & Technology, Mr. Yang Shaojun Consul for Science & Technology and Ms. Li Bei, General Manager, China Association for International Exchange of Personnel. ______________________________ |

||||

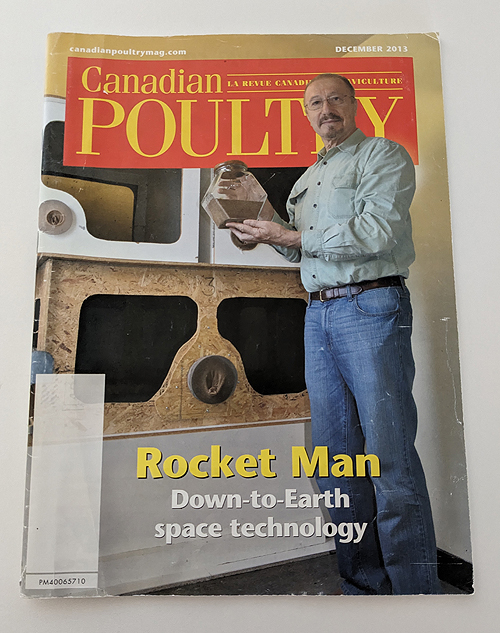

Mr. Ivan Milin, inventor of Milinator technology, was officially selected as a qualified nominee for the Manning Innovation Award. The Manning Innovation Award is one of Canada's most prestigious awards for Canadian innovators. ______________________________ |

||||

Dr. Mike Dixon, professor at Guelph University and Mr. Tim Nelson, Executive Director of the Poultry Industry Council, nominated Mr. Ivan Milin for the Manning Innovation Award. Click here to see endorsement letters. ______________________________ |

||||

|

Display of Cyclorganic fertilizer at a Hydroponics store in Mississauga, Ontario. ______________________________ |

||||

|

Display of Cyclorganic fertilizer at "Holland Industry" hydroponics store in North York, Toronto. ______________________________ |

||||

|

PACKAGING FOR MILINATOR FERTILIZERS Left – Plastic container with handle and re-usable lid ---------------- 4 Kg. ______________________________ |

||||

Ontario Commissioner for Environment Mr. Gord Miller and Mr. Glenn Munroe Policy and Decision Analyst, visited the Milinator prototype plant at the Arkell Research Station. To read the Commissioner's opinion click here.

______________________________ |

||||

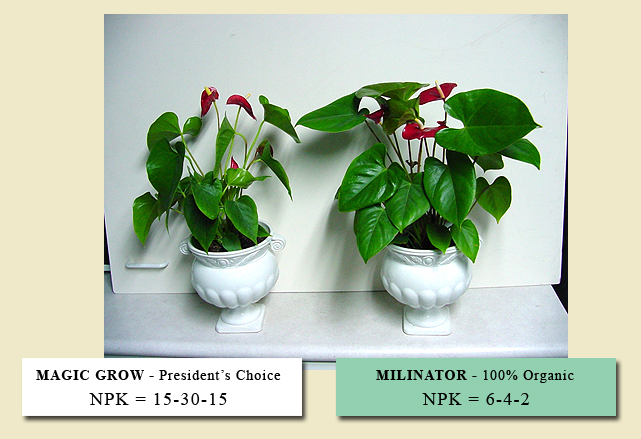

Encouraged by the Homegrown Hydroponics test, we repeated the comparison test on indoor plants.

______________________________ |

||||

Homegrown Hydroponics tested and compared their Dutch Nutrient Formula to Milinator 100% Natural hydroponics fertilizer.

______________________________ |

||||

|

Click here to view the letter. ______________________________ |

||||

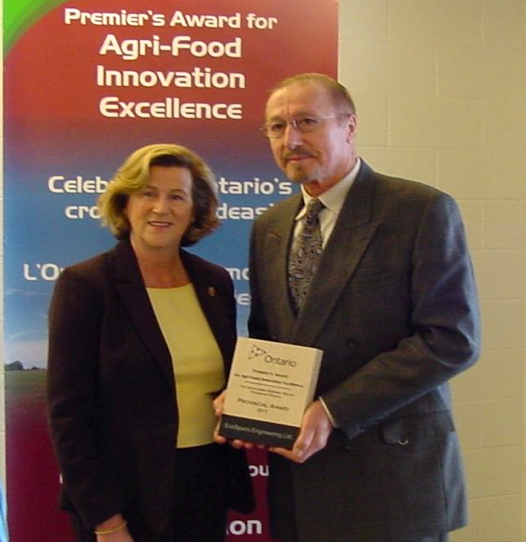

AGRI-FOOD INNOVATION AWARD

The Honorable Helena Jaczek, MPP for Oak Ridges-Markham and Ivan Milin, Inventor, Receiving Innovation Award from the Government of Ontario. Governments of Ontario and Canada also funded Milinator research & development and provided grants to build the first industrial size, automated mechanical processing plant in Southern Ontario. Milinator technology can always count on government's help regardless in which country or province it is being built. ______________________________ |

||||

OMAFRA agricultural engineer Mr. Hugh W. Fraser and Mrs. Christine Brown, Nutrient Management Field Crop Lead, regularly visited Milinator R&D lab at the Arkell Research Station and spent the day observing and reporting on our progress. They also collected and analyzed samples from different stages of the process. OMAFRA is interested in the possibility of using the Milinator process to recycle dead animals.

______________________________ |

||||

Mr. Ron Lackey, Feed Ingredients and Byproducts Feeding Specialist, Ontario Ministry of Agriculture, visited Milinator prototype plant at Arkell, Ontario. Please click here to see Mr. Lackey's letter of endorsement.

______________________________ |

||||

Arkell – Manual prototype

The first manual prototype built at the University of Guelph's Arkell Research Station. ______________________________ |

||||

In March 2010, the Engineering firm WALINGA Inc. and Milinator Technologies Inc. agreed to cooperate. Walinga would build the first Milinator mechanical prototype plan and later produce a full-sized commercial semi-automated plant. Walinga is a Guelph based engineering firm specializing in custom-made transportation equipment for the Agricultural Industry www.walinga.com. Walinga has servicing affiliates around the world and will also service Milinator equipment. ______________________________ |

||||

In December 2009, Milinator Technologies Inc. was incorporated. The company will license Milinator technology around the world and EcoSpace Engineering will conduct research and development in the field of Organic waste recycling.

______________________________ |

||||

Newspaper Article: Manure composted in 3 days.

(click here to view article) ______________________________ |

||||

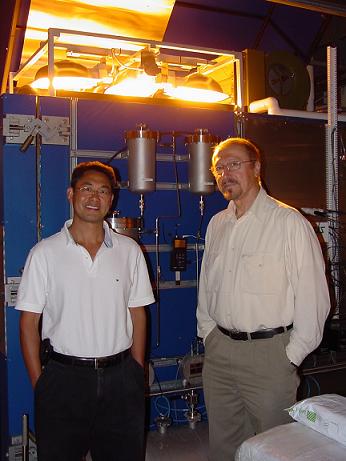

| Ontario Ministry of Agriculture and Rural Affairs approved $160,600.00 in funding for a joint .research program conducted by University of Guelph's Department of Environmental Biology and EcoSpace Engineering Ltd. The research project is conducted under leadership of Dr. Youbin Zheng, Adjunct Professor at the University of Guelph, Department of Environmental Biology. The scientific data generated from stage one will be used to both approve the use and sale of organic fertilizer, as well as the use of larvae and pupae as livestock feed. This scientific data will also be used for evaluating the positive environmental impact of MILINATOR Technology and thus paving the way for obtaining Carbon Credits. ______________________________

Dr. Youbin Zheng and Ivan Milin pose beside a Vacuum Chamber used to simulate growing conditions inside the low-pressure greenhouse domes that would be used on future human colonies on other planets.

|

||||

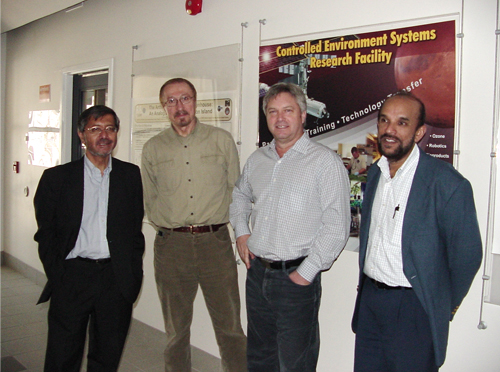

On March 24, 2009, Ivan Milin was invited to the University of Guelph’s Department of Environmental Biology to discuss his MILINATOR technology and the various ways in which the University could collaborate with EcoSpace Engineering Ltd. Participants of the meeting where: Dr. Michael A Dixon, Professor and Director of Controlled Environment System Research Facility. ______________________________

Dr. Michael Dixon and Ivan Milin pose in front of Small Hypobaric Chambers, used for research related to biological life support for the long term human space exploration. Dr. Dixon is the world’s leading expert in the field of Space & Advanced Life Support Agriculture.

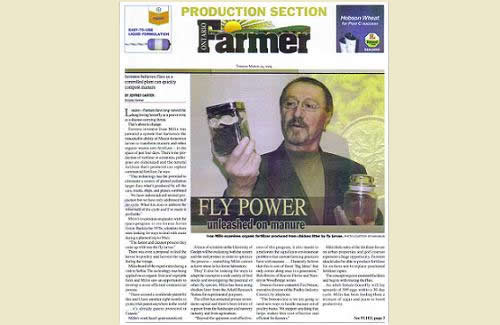

"Ontario Farmer" magazine has published an article about MILINATOR technology. To view the article please click here.

|

||||

Ivan Milin, president of EcoSpace Engineering Ltd. was a speaker at "The 3rd Annual Growing the Margins Conference and Exhibition". The topic of Mr. Milin's speech was: |

| TOTAL RECYCLING OF RAW MANURE BY USING FLY LARVAE |

___________________________________

On November 27th, 2008, on Thursday, at 2 PM, The Agri-Technology Commercialization Centre, 120 Research Lane, Guelph, Ontario, Canada, was officially opened. Ontario's Minister of Agriculture, Food and Rural Affairs, The Honourable Leona Dombrowsky was a Special Guest for the opening.

|

|

EcoSpace President Ivan Milin, presented his MILINATOR technology to the audience of Professional Engineers. The presentation was organized and hosted by The Association of Professional Engineers of Ontario, in Holyday Inn, Toronto Airport-East, Toronto, Ontario. ______________________________

|